Glassblowing, like all forms of art, takes a large amount of patience, creativity, and dedication. But blowing glass is by no means a new form of art. The process of utilizing glass as an art form has evolved over the centuries, but it originally began as early as 3500 B.C., with the ancient Egyptians using glass to make beads. The Mesopotamians were the next to move the glass art movement along (at approximately the 6th century B.C.), as their artisans began creating other glassware (specifically vases), using a new method of melting down glass and then wrapping it around a hard substance.

The huge step in the transformation of the use of glass art (and the first time glass was blown) occurred during the Roman Empire. Roman craftsmen took a metal tube to blow holes into glass that they had heated to extremely high temperatures. They molded this hot glass into specific shapes and designs for glass containers by blowing into the metal tube. This was the origination of the modern form of glassblowing that we see today, although obviously the process is quite different now. The Romans’ techniques with blowing glass spread throughout the world as the centuries passed, and the steps required and technology used grew exponentially with time. In ancient times, glass was a highly sought-after commodity and cultures worked tirelessly to find innovative ways to produce as much glass as possible.

By the Middle Ages, glass creation could be found in countries throughout the world. The Italians specifically became enamored with the creation of glass. Venice became a global hub in the creation of glass, with reports of as many as 8,000 different glass artisans inhabiting the city in the 12th century. Glassblowing became such a large industry in Venice that laws were created that prohibited glass and glass artists from being imported into the city. By the beginning of the 13th century, concerns rose about the historically rich city being burned down from the numerous glassblowing factories. A law was passed that moved artists, factories, and furnaces to the island of Murano. There, the craft of glassblowing further evolved and the Venetians were able to protect their glassblowing secrets.

Jumping forward in history to the 20th century, a pivotal point in the advancement of glassblowing techniques occurred in America in 1962. Harvey Littleton, a ceramics professor at the University of Wisconsin, had visited numerous glassblowing industrial factories in Europe and believed that the process could be done in a small studio. When he returned to the University of Wisconsin, Littleton was granted use of storage sheds on the grounds of the museum to set up a one week workshop. Littleton brought a small pot furnace he had crafted at his farm and Norm Schulman (a pottery instructor at the university’s museum school) helped him hook it up in the museum’s garage. Dominick Labino (a chemist, engineer, and director of research for Johns Manville Corporation), provided a low melting glass formula to Littleton. Labino oversaw the conversion of Littleton’s pot furnace into a day tank by supplying it with marbles that had a low melting point that he originally created for making fiberglass. Using Littleton’s pot furnace and Labino’s formula, glass was created that proved to be extremely efficient and made glassblowing a more simple process. The ten participants of the workshop spent the week experimenting and handblowing glass into various art forms.

industrial factories in Europe and believed that the process could be done in a small studio. When he returned to the University of Wisconsin, Littleton was granted use of storage sheds on the grounds of the museum to set up a one week workshop. Littleton brought a small pot furnace he had crafted at his farm and Norm Schulman (a pottery instructor at the university’s museum school) helped him hook it up in the museum’s garage. Dominick Labino (a chemist, engineer, and director of research for Johns Manville Corporation), provided a low melting glass formula to Littleton. Labino oversaw the conversion of Littleton’s pot furnace into a day tank by supplying it with marbles that had a low melting point that he originally created for making fiberglass. Using Littleton’s pot furnace and Labino’s formula, glass was created that proved to be extremely efficient and made glassblowing a more simple process. The ten participants of the workshop spent the week experimenting and handblowing glass into various art forms.

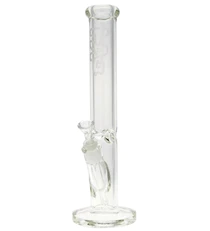

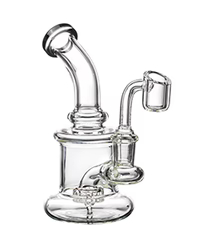

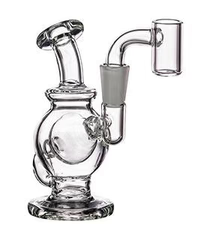

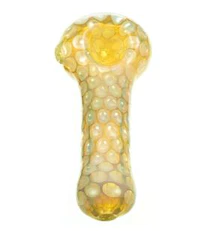

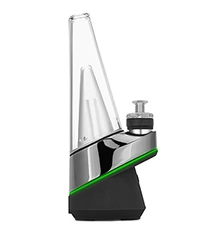

Harvey Littleton’s experimentation on the University of Wisconsin campus not only proved that he was correct in his belief that high quality glass could be blown in a small studio, it also directly paved the way for the glassblowers of today. Glassblowers of today work in small studios, not large industrial factories, thanks to Littleton’s tests and observations. From the Egyptians to the Italians to 20th century Americans, the techniques for blowing glass have adapted and grown into present day practices. These methods are used in creating the dab rigs, glass bongs, bubblers, and hand pipes that are sold throughout the industry today.