Constancy validates Science. Recorded experiments can be replicated over and over with similar results (otherwise, it wouldn’t be Science). Take these two scientists for instance: 8th century Persian chemist Abu Musa Jabir ibn Hayyan (considered the “Father of Chemistry”) and 20th century heady glass blower Bob Snodgrass (considered the “Father of Heady Glass Pipes”). Obviously men of different backgrounds and millennia, but one thing they both realized in their experiments was that adding powdered metal oxides into molten glass created wondrously colored glass.

How Do You Make Colored Glass?

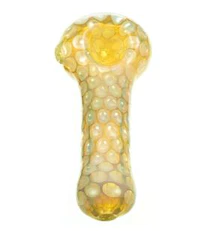

Just as Hayyan shared his discovery with his peers (which led to stained glass, marbles, and jewelry of the ancient world), Snodgrass shared his discovery to the world of functional heady glass. Specifically, Snodgrass was the first heady artist to produce fumed glass, which is created when silver and gold powder are heated to release fumes that give clear glass a semi-opaque backing. Silver fuming creates hues ranging from blue to purple, while gold fumes produce pink, green, and orange patterns. This knowledge allowed heady glass artists to make high quality pipes with vibrant color and patterns.

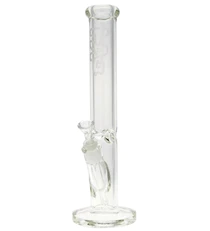

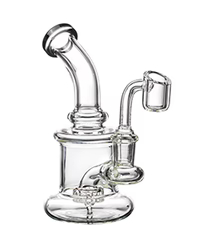

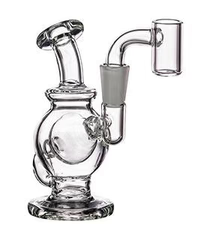

Snodgrass’ innovation was the culmination of the glass community’s desire to incorporate colored glass into their pipes. The modern glassblower now has several methods at her/his disposal. The clear glass base for any borosilicate pipe is called the cullet, which is heated and shaped before anything is added. The two most common ways to then add color is to add frit or cane to the cullet while blowing. Frit is powdered or ground colored glass that the cullet is rolled through in order to fuse together. The frit then melts into the cullet, which incorporates color. Frit can range from talc-like powder to granite sized pebbles. The size affects whether the color is mostly solid or a spotty design. Cane is a colored glass bar that is heated then stretched to create strips of color. Cane is the basis for stripe patterns such as rainbows and wig-wags.

How Do You Make Dichroic Glass?

Besides fumed glass, the color-form most associated with hand pipes is dichroic glass. Dichroic glass appears to be different colors when light is shone through it vs. when light reflects against it. This reflective phenomenon is known as thin-film physics, the same reason why you see swirling rainbow patterns in a soap bubble, floating colors from oil on water and the dramatic colors of dragonfly wings. Dichroic glass’ reflectiveness is due to a multi layer coating created by a highly technical vacuum deposition process. Dichroic glass originates in aerospace technology: NASA developed dichroic glass for use in satellite mirrors in the early 90s and also used it for re-entry tiles on space shuttles. Making dichroic glass requires a complex processing technique and is only made by a handful of manufacturers that have high-tech equipment like high temperature vacuum chambers, vaporizing electro-guns, and high temperature kilns. As such, most glassblowers buy the coating from these manufacturers and apply it to glass as a vapor during the blowing process.

Given the premium put upon relaxation while smoking, it’s only natural that so many smokers desire for their pieces to have aesthetically-pleasing color. Color theory has shown us that certain hues can change moods, which pairs well with your favorite bong or bubbler. Keep this in mind when shopping for your next piece, as it could go beyond just a method of smoking and become a steadfast companion for years. And if you’re in the market for a new pipe, head to DankStop.Com and see our rainbow of colored bongs, bubblers, and and hand pipes!