Extreme Technique

In Santa Cruz, California, shredding is not a word to be used lightly. The beachfront city is known for its extreme sports culture, particularly skateboarding and surfing. To “shred” means to skate/surf so intensely that it risks destruction of your board/skatepark/body. For spectators, those risks make every successful grind, aerial and cutback even more impressive. The coolness of shredding wasn’t lost on Santa Cruz Shredder; the grinder company’s promotional montage videos feature extreme sportsmen performing insane stunts alongside their engineers producing and testing their signature products. The crew at Santa Cruz Shredder can appreciate the free spirit of these athletes: they have become leaders in the market of herb grinders by applying techniques other companies wouldn’t have dreamed of.

Better Teeth

Of all the tools used in the smoking process, the shredder can seem too straightforward to improve upon. Put in herb, shred it, and you’re done. Santa Cruz Shredder recognized that there’s more to the story: low-end grinders have sharp-edged teeth, which seems like the right choice until you realize that sharp edges dull over time. This dulling makes turning your shredder more difficult over time.The increased pressure necessary to turn will fatigue the metal, which can lead to the teeth bending and eventually breaking. This breaking can lead to metal debris in your herbal blend. Santa Cruz Shredder’s founder Matt Hansen had a solution to this issue in 2010: use square teeth that won’t get dull from metal fatigue and provide a consistent grind with every use. Comparable grinders cut once, letting large chunks pass through the holes without further grinding. Their grinders’ teeth are designed to cut multiple ways, so herbs come out perfectly ground.

Better Threading

Santa Cruz Shredder sought to improve more than the shredding quality of herb grinders. For example: one of the biggest problems with older grinders is that the threading (the metal lines that allow you to screw the pieces together) often wear away over time, which locks the grinder shut. This can make it impossible to open your shredder. Santa Cruz Shredder developed a thread pattern that eliminates the sticking of screw-together parts. They anodize the threaded surfaces (an electrical process that hardens the metal) so it won’t wear down. The exterior of their grinders is also anodized, making it scratch resistant. In addition, they invented the “7-Catch Design” that simplifies screwing together their grinders. Most grinders have to be rotated until the user eventually finds the thread catch, and then have to continue to be screwed until it’s secure. This causes additional wear & tear, the possibility of cross-threading, and a confusing amount of turns.

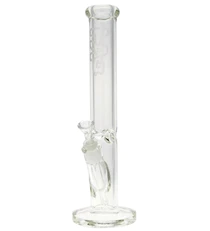

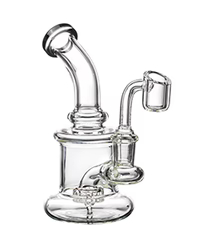

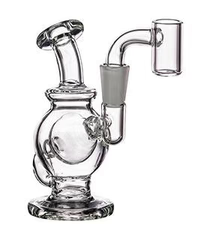

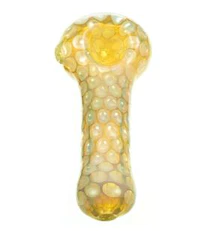

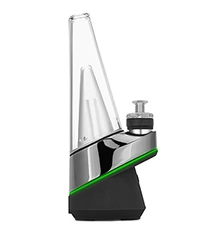

Dab Tools

Riding the wave of interest in oil rigs, Santa Cruz Shredder has also become an industry leader in dab tools. The process of dabbing requires tools that withstand extreme heat for years without breaking down. Santa Cruz’s emphasis on durable construction makes them perfect for the task; they use Grade 2 Titanium (the best quality titanium available) for all of their dab nails, dabbers and carb caps. Santa Cruz Shredder is now a sought-after brand for dab tools: 420 Titanium.com named their Shredder Omni as one of the Top 5 nails for 2015.

The Team Behind It All

Santa Cruz Shredder was originally formed by engineer Mark Hansen, hip-hop artist Berner, and an unnamed NASA scientist. Together, these three combined corporate vision, style, and engineering prowess to create a company that dominated in two niche fields. The team is now working on a grinder that will be 18 inches in diameter – with a hand crank – to grind as much as a quarter-pound of herb at once. The Santa Cruz Shredder team believes this device will be ideal for collectives rolling their own cigarettes. Hansen said in an interview with Culture Magazine that “our motto is all about innovation, making things different, making things function better.” So far, it looks like they’ve succeeded.